OUR PROCESS

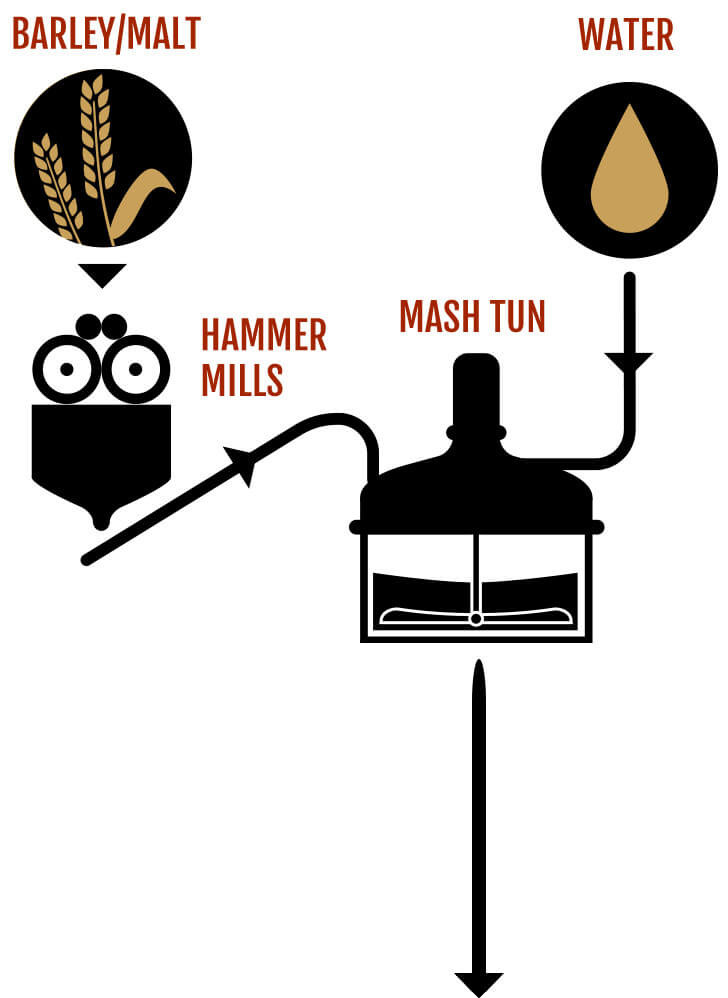

Our beers are crafted in Scotland honouring the Tennent family’s original recipes since 1556. The base ingredients for our beers are simple and genuine, and they haven’t changed a bit; malted barley, hops, yeast and water.

These ingredients are sourced against stringent specifications from approved suppliers. Our water, (which is really what makes our beer special), comes from Lock Katrine – an ancient source of pure highland water that has quenched the thirst of many a Scotsman throughout the ages, and is still the main source for the city of Glasgow. Our malted barley is sourced from local farms, and we work closely with Scottish growers to ensure we are only supplied with the best local produce.